TPO and PVC

TPO and PVC For Commercial Applications

TPO and PVC

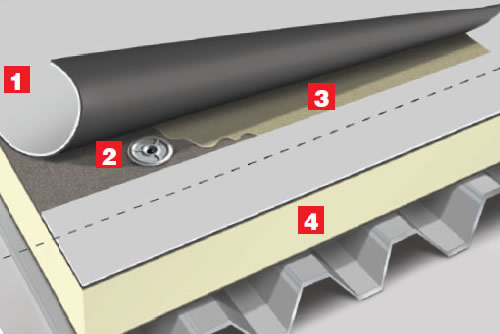

Thermoplastic Polyolefin (TPO) and Poly Vinyl Chloride (PVC) are thermoplastic roof systems that are both white and highly reflective roof membranes. These roofs provide excellent weathering characteristics and are highly resistant to ultraviolet light and most chemicals. The membranes have a reinforced scrim and are puncture and tear resistant. TPO roofs have outstanding seam strength because sheets are welded together using hot air. These types of roof systems are light weight and well suited for roof-over applications. TPO and PVC roof systems are typically installed in one of two ways: Mechanically attached- the roof membrane is affixed to the structural deck with mechanical fasteners. Fully adhered- the membrane is bonded directly to the affixed insulation board or other roofing membrane. Most of the major manufacturers produce Energy Star Rated TPO roofing membranes which must, by definition, have an Initial Solar Reflectance value greater than or equal to 0.65. The benefits to having an Energy Star Rated roofing system are multi-fold: Savings on cooling bills will accrue immediately. HVAC systems undergo less stress and enjoy extended service life. Energy Star Rated TPO roofing reduces carbon emissions and helps lessen the heat island effect.